|  |

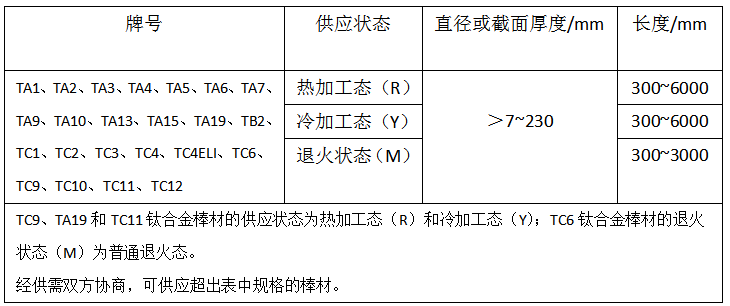

Product Introduction (titanium rods):

Materials: Titanium and its alloy.

Available Specification: Manufactured to standards or customer requested.

Product Grade: TA1/TA2/TA8/TA9/TA10/TC4/N4/N6/Ni201/Ni200/Zr702 etc.

Diameter and Length: Available to customer requests.

Production Method: Forging, squeezing.

Application: Industry, medical, aerospace.

Executive Standard: National standard GB, US standard ASTM, and Russian standard ГОСТ, ТУ.

Surface of the Product:black surface、machined surface、polished surface

Ps: Round and rectangular rods are available as required by the customer.

For more grade and form, please contact us.

Technical Requirements for Titanium Rods:

1.The surface of the drawn bar should be smooth and clean, and no cracks, peeling, porosity, inclusions, rough drawing channels, ring marks and green rust defects are allowed. Scratches, pits, spots and other defects that are limited, and not making the bar diameter exceed the allowable deviation are allowed. Slight straightening marks, oxidation color and darkening are allowed.

2.The surface of the extruded bar should not have cracks, bubbles and skinning or other defects. It is allowed to have limited defects that do not make the diameter of the bar exceed the allowable deviation.

3.Bar fracture should be dense, no shrinkage. Defects such as porosity, delamination and interlayer that exceed the specified limits are not allowed.

Technical Standards Referenced:black surface、machined surface、polished surface

1 GB228 metal tensile test method

2 GB/T3620.1 brand and chemical composition of titanium and titanium alloys

3 GB/T3620.2 allowable deviation of chemical composition of titanium and titanium alloy processing products

4 GB 4698 sponge titanium, titanium and titanium alloys chemical analysis methods

5 GB/T2965-2007 titanium and titanium alloy bars

|  |

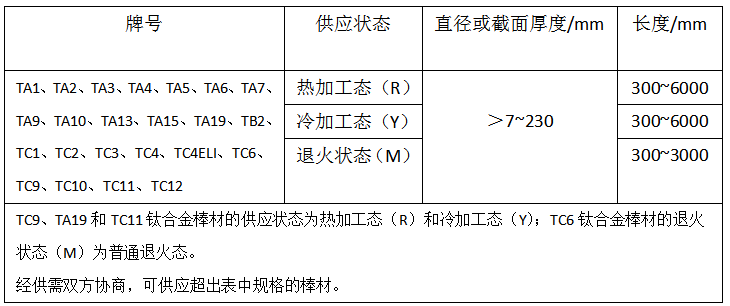

Product Introduction (titanium rods):

Materials: Titanium and its alloy.

Available Specification: Manufactured to standards or customer requested.

Product Grade: TA1/TA2/TA8/TA9/TA10/TC4/N4/N6/Ni201/Ni200/Zr702 etc.

Diameter and Length: Available to customer requests.

Production Method: Forging, squeezing.

Application: Industry, medical, aerospace.

Executive Standard: National standard GB, US standard ASTM, and Russian standard ГОСТ, ТУ.

Surface of the Product:black surface、machined surface、polished surface

Ps: Round and rectangular rods are available as required by the customer.

For more grade and form, please contact us.

Technical Requirements for Titanium Rods:

1.The surface of the drawn bar should be smooth and clean, and no cracks, peeling, porosity, inclusions, rough drawing channels, ring marks and green rust defects are allowed. Scratches, pits, spots and other defects that are limited, and not making the bar diameter exceed the allowable deviation are allowed. Slight straightening marks, oxidation color and darkening are allowed.

2.The surface of the extruded bar should not have cracks, bubbles and skinning or other defects. It is allowed to have limited defects that do not make the diameter of the bar exceed the allowable deviation.

3.Bar fracture should be dense, no shrinkage. Defects such as porosity, delamination and interlayer that exceed the specified limits are not allowed.

Technical Standards Referenced:black surface、machined surface、polished surface

1 GB228 metal tensile test method

2 GB/T3620.1 brand and chemical composition of titanium and titanium alloys

3 GB/T3620.2 allowable deviation of chemical composition of titanium and titanium alloy processing products

4 GB 4698 sponge titanium, titanium and titanium alloys chemical analysis methods

5 GB/T2965-2007 titanium and titanium alloy bars