|  |  |

Product introduction:

Common materials: titanium and titanium alloy, nickel and nickel alloy, zirconium, high temperature corrosion resistant alloy

Product brand: ta1/ta2/ta8/ta9/ta10/tc4/n4/n6/ni201/ni200/zr702/inconel600, etc

Width and length: customizable (standard plate size: 1000*2000 or 1500*6000)

Thickness: 0.3-50mm

Uses: industrial, medical, aerospace

Manufacturing method: hot rolling and cold rolling

Executive standard: national standard GB, American Standard ASTM

Product surface: acid washed surface, bright surface, etc

Please contact us directly for more specifications, sizes and brands.

Characteristics of titanium:

Titanium has the advantages of low density, high strength, good corrosion resistance, low thermal conductivity, non-magnetic, good high and low temperature performance, and has been widely used in aviation, aerospace, ships, petroleum, chemical industry, electric power and other fields.

The color of titanium is silver white. Titanium is a highly active metal and belongs to polycrystalline metal. Pure titanium has two crystal forms, which is below 882 ℃ α Crystal form, in close hexagonal lattice; Stable from 882 ℃ to melting point β The crystal form is body centered cubic lattice. Industrial pure titanium is α Phase.

Industrial pure titanium can withstand forging, rolling, extrusion and other pressure processing. It is similar to stainless steel in mechanical and chemical properties, and is classified as a rare light metal in metal classification.

Mechanical properties of pure titanium

The density of titanium is 4.51g/cm ³, It is 57% of steel, 50% of copper and nickel, 1.8 times of aluminum, and the tensile strength of pure titanium σ b. Between 265-620mpa, titanium alloy can generally reach 690-1180mpa. The specific strength of titanium alloy can reach 3.5 times that of stainless steel, 1.3 times that of aluminum, and 1.7 times that of magnesium alloy. Here, the specific strength is the ratio of strength to specific gravity.

Chemical properties of titanium

Titanium is a highly active metal, and its oxide is extremely stable. Because titanium is easy to form a thin and solid oxide film in an oxygen-containing environment, this film can resist the erosion of oxidation solution, so titanium has excellent corrosion resistance.

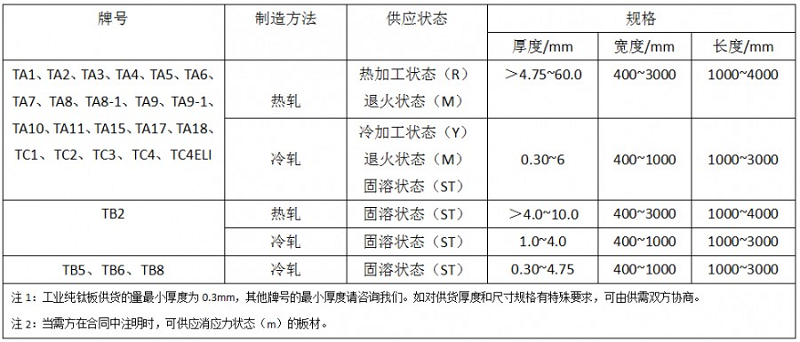

Titanium plate supply status table

Plate inspection and manufacturing standards

1 gb/t3620.1 grades and chemical compositions of titanium and titanium alloys

2 gb/t3621-2007 titanium and titanium alloy plates

3 gb/t3622-1999 titanium and titanium alloy strip and foil

4 gb/t14845-2007 titanium plates for plate heat exchangers

5 gb/t2054-2005 nickel and nickel alloy plates

6 gb/t13810-2007 titanium and titanium alloy processing materials for surgical implants

|  |  |

Product introduction:

Common materials: titanium and titanium alloy, nickel and nickel alloy, zirconium, high temperature corrosion resistant alloy

Product brand: ta1/ta2/ta8/ta9/ta10/tc4/n4/n6/ni201/ni200/zr702/inconel600, etc

Width and length: customizable (standard plate size: 1000*2000 or 1500*6000)

Thickness: 0.3-50mm

Uses: industrial, medical, aerospace

Manufacturing method: hot rolling and cold rolling

Executive standard: national standard GB, American Standard ASTM

Product surface: acid washed surface, bright surface, etc

Please contact us directly for more specifications, sizes and brands.

Characteristics of titanium:

Titanium has the advantages of low density, high strength, good corrosion resistance, low thermal conductivity, non-magnetic, good high and low temperature performance, and has been widely used in aviation, aerospace, ships, petroleum, chemical industry, electric power and other fields.

The color of titanium is silver white. Titanium is a highly active metal and belongs to polycrystalline metal. Pure titanium has two crystal forms, which is below 882 ℃ α Crystal form, in close hexagonal lattice; Stable from 882 ℃ to melting point β The crystal form is body centered cubic lattice. Industrial pure titanium is α Phase.

Industrial pure titanium can withstand forging, rolling, extrusion and other pressure processing. It is similar to stainless steel in mechanical and chemical properties, and is classified as a rare light metal in metal classification.

Mechanical properties of pure titanium

The density of titanium is 4.51g/cm ³, It is 57% of steel, 50% of copper and nickel, 1.8 times of aluminum, and the tensile strength of pure titanium σ b. Between 265-620mpa, titanium alloy can generally reach 690-1180mpa. The specific strength of titanium alloy can reach 3.5 times that of stainless steel, 1.3 times that of aluminum, and 1.7 times that of magnesium alloy. Here, the specific strength is the ratio of strength to specific gravity.

Chemical properties of titanium

Titanium is a highly active metal, and its oxide is extremely stable. Because titanium is easy to form a thin and solid oxide film in an oxygen-containing environment, this film can resist the erosion of oxidation solution, so titanium has excellent corrosion resistance.

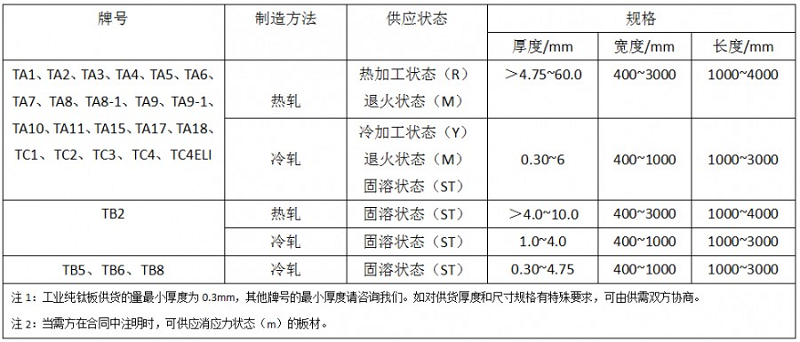

Titanium plate supply status table

Plate inspection and manufacturing standards

1 gb/t3620.1 grades and chemical compositions of titanium and titanium alloys

2 gb/t3621-2007 titanium and titanium alloy plates

3 gb/t3622-1999 titanium and titanium alloy strip and foil

4 gb/t14845-2007 titanium plates for plate heat exchangers

5 gb/t2054-2005 nickel and nickel alloy plates

6 gb/t13810-2007 titanium and titanium alloy processing materials for surgical implants